Nayden Chivarov

Institute of Information and Communication Technologies at Bulgarian Academy of Sciences – Sofia, Bulgaria

e-mail: nchivarov@gmail.com

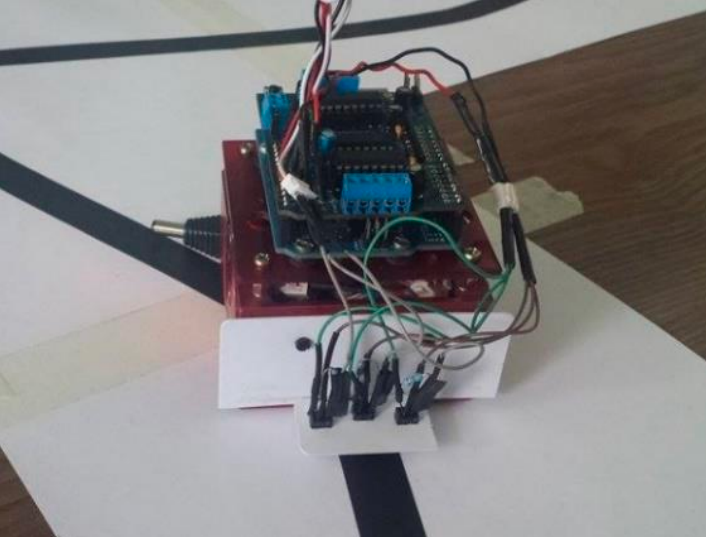

Abstract: The paper is dedicated to ERASMUS + project ”NITRO Clubs EU”. The project envisions to create the Network of IcT Robo Clubs by using multifunctional mobile robot platforms for each participant. In this paper is presented the application of Educational Mobile Robot for Line Following. Research and development of Mechanical System, Electronical and Control System of the Robot and Line Following Algorithm are described.